Products

Products

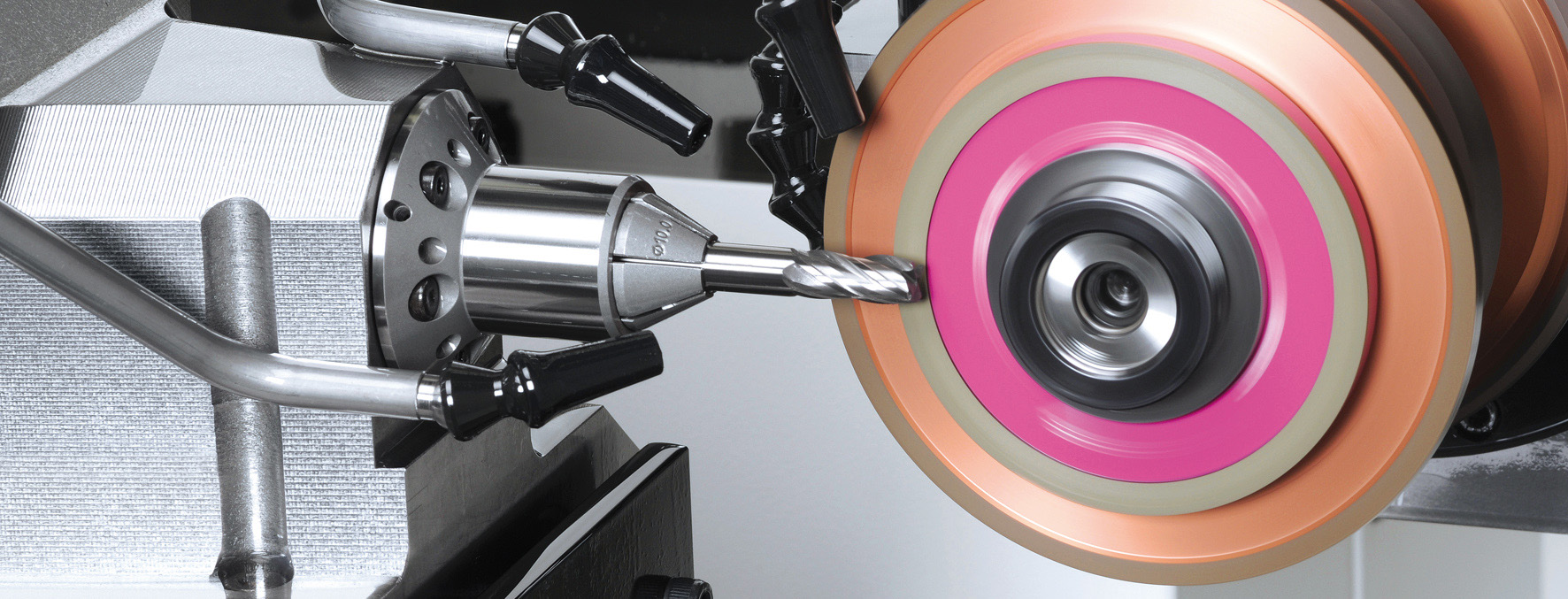

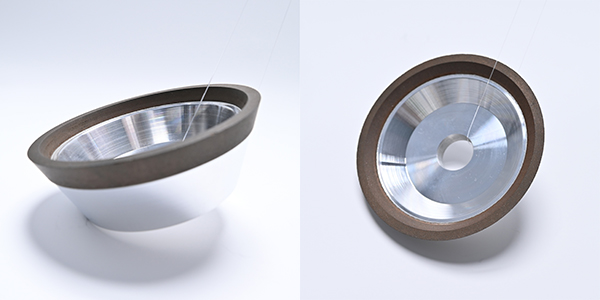

12V9 Grinding Wheel for Tungsten Carbide End Mills

Diamond grinding wheels are essential tools used in various industries for precision grinding operations on hard materials like carbide, ceramics, and composites. In this guide, we will explore the benefits, applications, and considerations associated with diamond grinding wheels, aimed at optimizing your grinding processes for hard alloys.

Workpiece Materials: Tungsten carbide steel, High speed steel (HSS), Stainless drill, End mill and Reamer etc.

Application: Flute Grinding, Gash Grinding, End facing, Clearance angle Cylindrical grinding.

Structure: Fluting (1A1, 1V1), Gashing and clear edge (1V1, 12V9), Relief angle (11v9)

Alias: CNC Grinding Wheel, Diamond Flute Wheel

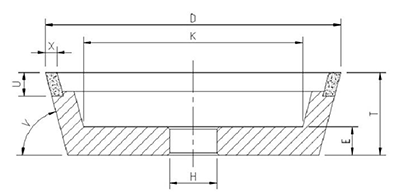

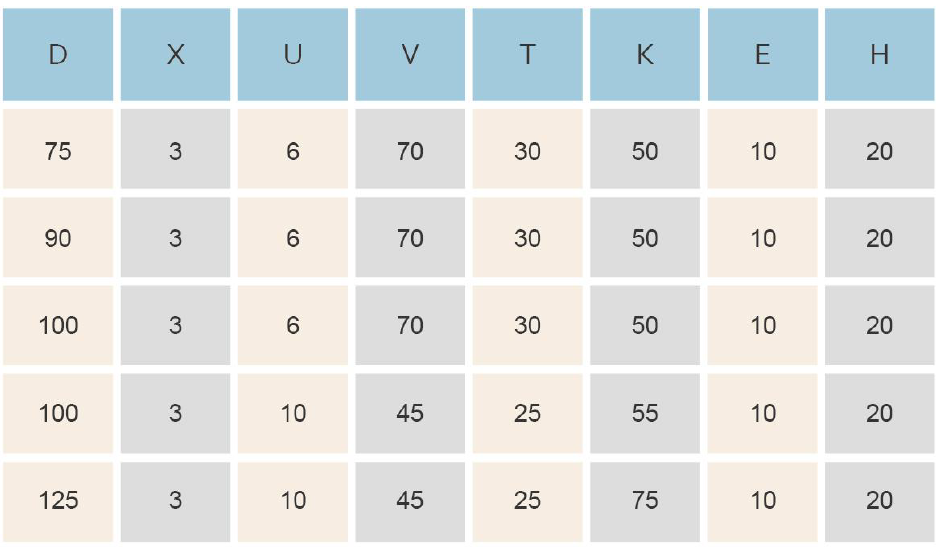

Unit:mm

Customized grinding tool can be manufactured on request

Benefits of Diamond Grinding Wheels:

- High precision, for grooving and grinding

- Exceptional Hardness: Diamond grinding wheels are renowned for their exceptional hardness, making them highly resistant to wear and ensuring prolonged lifespan.

- Precision Grinding: Diamond grinding wheels offer precise and consistent grinding results, enabling high-quality surface finishes and meeting strict tolerance requirements.

- Efficient Heat Dissipation: The excellent heat dissipation properties of diamond help prevent material deformation during grinding, ensuring workpiece integrity.

- Reduced Downtime: With longer lifespan and minimal dressing requirements, diamond grinding wheels minimize downtime and increase overall productivity, leading to cost savings.

Applications of Diamond Grinding Wheels:

- Tool and Die Manufacturing: Diamond grinding wheels are commonly used for sharpening cutting tools and dies made from hard alloys like carbide.

- Aerospace Industry: Diamond grinding wheels play a crucial role in machining aerospace components made from tough materials like titanium alloys and ceramics.

- Automotive Manufacturing: In automotive production, diamond grinding wheels are used for precision grinding of engine components and transmission parts.

Considerations for Using Diamond Grinding Wheels:

- Proper Selection: Choosing the right diamond grit size, bond type, and wheel specifications is crucial for achieving desired grinding results.

- Coolant Usage: Using coolant or lubricant during grinding helps control heat buildup and improves surface finish.

- Dressing Techniques: Regular dressing of diamond grinding wheels ensures consistent wheel sharpness and prolongs wheel life.

In conclusion, diamond grinding wheels are indispensable tools for precision grinding of hard alloys in various industries. Their exceptional hardness, precision grinding capabilities, and heat dissipation properties make them ideal for achieving high-quality finishes and tight tolerances. By selecting the appropriate wheel specifications and employing proper grinding techniques, you can optimize your grinding processes for superior results on hard alloy materials. Explore our range of diamond grinding wheels today to elevate your grinding operations to the next level of efficiency and precision.

About price:

Please contact us:

cartroyal@gmail.com Wechat:18117002521