Products

Products

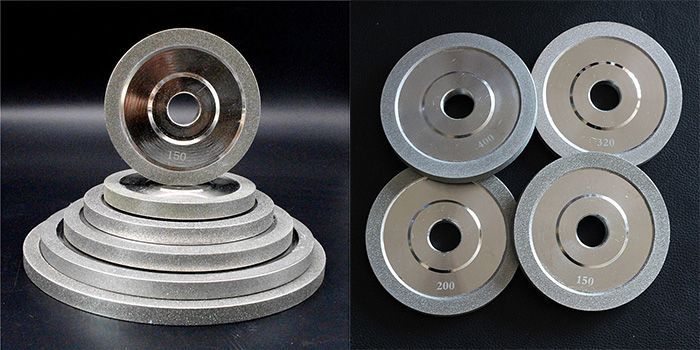

Electroplated grinding wheels for grinding ceramics and hard alloys are highly specialized tools that offer several distinct advantages.

These grinding wheels are designed with precision and durability in mind. The electroplated bond provides a secure attachment of the abrasive particles, ensuring stability and consistency during the grinding process. This makes them ideal for applications where high accuracy and surface finish are required.

When it comes to grinding ceramics, these wheels are capable of handling the hard and brittle nature of ceramic materials. They can achieve smooth and flat surfaces with minimal chipping or cracking. The abrasive particles, often made of superabrasives like cubic boron nitride (CBN), are extremely hard and wear-resistant, enabling long service life even when working with tough ceramics.

For hard alloys, the electroplated grinding wheels are equally effective. They can efficiently remove material from hard alloy components without sacrificing precision. The wheels can be customized in terms of grit size and wheel shape to meet the specific needs of different hard alloy grinding applications.

In addition, these grinding wheels offer good heat dissipation properties, reducing the risk of heat damage to the workpiece. They are also relatively easy to dress and maintain, ensuring consistent performance over time.

Overall, electroplated grinding wheels for ceramics and hard alloys are essential tools for industries that require high-quality grinding of these difficult-to-machine materials. Their combination of precision, durability, and performance makes them a valuable asset in various manufacturing processes.