Welcome to China Zhengzhou Jinzuan

Email: cartroyal@gmail.com

News

News

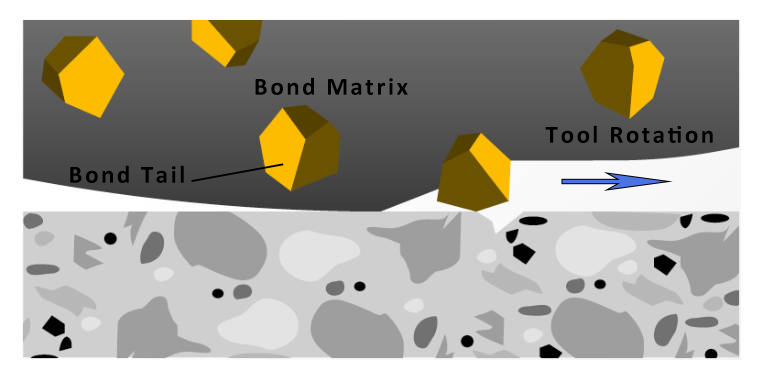

Diamond & CBN Tools represent the highest engineering of cutting and grinding technology. These tools use their unparalleled hardness and durability of diamonds to perform tasks beyond the capabilities of conventional tools. Essential across various industries, from advanced manufacturing to stone fabrication, diamond tools excel in processing the hardest and most challenging materials. They are capable of working with materials that have a hardness of 40 on the Rockwell scale and above, efficiently machining materials that are often challenging or even unmanageable for traditional abrasives, carbide, and high-speed steel tools.

CBN tools utilize cubic boron nitride, a synthetic material almost as hard as diamond, designed for machining ferrous materials. CBN tools are highly effective in high-speed cutting and heavy-duty grinding due to their excellent thermal stability and chemical inertness with ferrous materials. CBN tools are used primarily for machining ferrous metals.

Key Features of Diamond & CBN Tools:

- Exceptional Hardness: Diamond & CBN are the hardest known natural material, allowing diamond tools to cut and grind the toughest materials with ease.

- Superior Wear Resistance: Diamond & CBN tools have a long lifespan due to their resistance to wear, maintaining cutting efficiency over extended use.

- High Thermal Conductivity: Diamond & CBN effectively dissipate heat, reducing the risk of thermal damage to both the tool and material.